Lester Buildings: 75 Years Standing the Test of Time

Answer: We’re all celebrating diamond anniversaries in 2022!

Just think, three-quarters of a century ago, in 1947:

- Topps Chewing Gum Company introduced what was to become a favorite treat for American kids.

- AT&T Bell Laboratories demonstrated the transistor for the first time and opened the door to our digital future.

- Nabisco launched a new snacking sensation.

- And Lester Buildings emerged from a metal Quonset hut franchise, whose products were popular as military barracks during the post-World War II economic boom.

A legacy with humble beginnings

Here at Lester, we’re incredibly proud of our 75-year legacy. Interestingly, our success today as a leading manufacturer and builder of custom, pre-engineered post-frame building systems can be traced to rather modest beginnings.

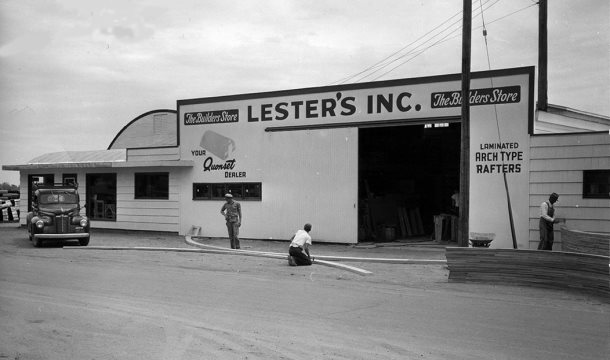

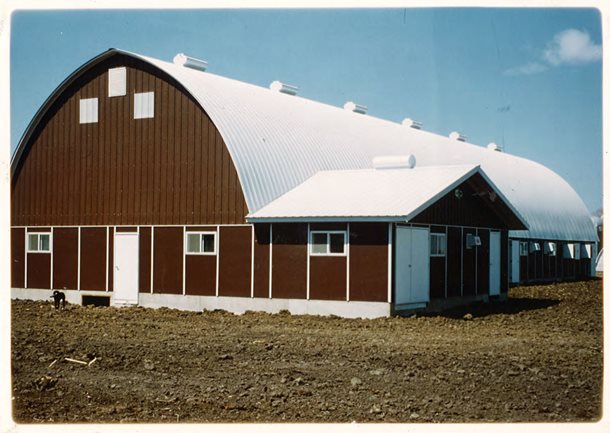

Known in 1947 as Lester’s, Inc., our company was founded by a group of entrepreneurial men who housed the business in a 2,400 square foot warehouse in Lester Prairie – the central Minnesota town where our operations are still headquartered today. When then-general manager Art Schwichtenberg bought the business in 1954, he steered our company toward selling glue-laminated Gothic arch agricultural and buildings. Under his leadership, Lester’s developed Insl-WallTM panels and the first Wingspan pole barn in the 1960s.

Original Office/Plant

Gothic-Arch Dairy Barn with Insl-Wall Parlor

With Art at the helm, Lester’s also grew from a local lumber yard selling Quonsets and pole barns in central Minnesota to a major regional building supplier with salespeople and construction crews in seven states. By 1977, our company celebrated its 30,000th building sold. Eager to expand beyond the Upper Midwest, Lester’s began selling to independent dealers in 1984. After 32 successful years with more than 49,000 buildings constructed, Art retired and sold the company to Butler Manufacturing, the largest steel building manufacturer in the world at that time.

Butler, with its national distribution of grain bins and steel buildings, increased our company’s manufacturing capabilities and distribution network by selling to contractors across the country and opening three new Lester manufacturing facilities. Through these efforts, Lester became a nationally known post-frame building company with products and services available in two-thirds of the United States.

New millennium brings change

When a young general manager by the name of John Hill came onto the Lester scene in 1988 to open and operate the company’s new Clear Brook, Va., manufacturing plant, the die was cast for our company’s next evolution.

“Post frame construction, at the time, was still focused on agriculture,” John recalls. “But there isn’t as much agriculture on the East Coast as there is in the Upper Midwest, so that’s where we began to broaden our product mix to include equestrian and commercial facilities.”

As Lester’s product lines grew, so did John’s career. He expanded his experience by taking on sales and marketing roles and earning promotions along the way. In 2000, John became Lester’s fifth president.

He had been running the business for about four years when Butler Manufacturing fell on hard times during the recession of 2001 – 2002. An Australian group, BlueScope Steel, purchased the entire Butler corporation – but with the intent to spin off several divisions, including Lester. That’s when John and six other Lester managers saw an opportunity to bring the company back into local, private ownership. Although none of the seven managers had ever owned a company before, they successfully bought Lester Buildings in 2004 and never looked back.

John and his co-leaders have truly brought Lester Buildings into the 21st century. Among their significant accomplishments:

Expanding manufacturing

Prior to the group’s ownership, our company manufactured all the wood components in our structures, but everything else was purchased from other suppliers. “We saw an opportunity to increase profit by making more of our own product,” John says. “Nearly every one of our buildings has steel cladding and trim, which represents about a third of the value of the buildings we make. We now make our own steel and trim and that’s proven to be a good, strategic decision. We can more quickly serve our customers, shorten lead times and improve the quality of the product we provide.

Investing in technological innovations

Among the major technological upgrades that occurred under John’s stewardship is a computer pricing program that offers customers flexibility in designing their building right at their own desktop. “We were at the forefront of computerized pricing and design software in our industry,” John notes.

In late 2021 we launched Dream Planner, a custom 3D design program allowing consumers to design their dream building. It is quickly becoming one of our most visited pages on our website.

“In addition, we continually invest in our proprietary engineering design software so we can design more and more complex structures,” he adds. “And, in 2017, we invested heavily in our enterprise resource planning (ERP) system to advance inventory management and control the quality of shipments.”

Looking toward the next 75 years

“I was always impressed with Lester’s legacy, starting in 1947,” John, who is now our company’s CEO, says. “It’s really important to me that Lester continues to thrive after I retire. People are building their lives and their livelihoods around this business, and I want to make sure that continues.”

To that end, John has been transitioning the business to the next generation of leaders: current president Mark Billstrom, CFO Melanie Hoof, VP of Engineering Services Ted Helmink and VP of Manufacturing Tyler Bennett.

Melanie Hoof, Mark Billstrom, Tyler Bennet, Ted Helmink

“These four key leaders are gradually buying into the ownership of the business and the entire buy-out will be completed in the next couple of years,” John explains. “We all have a passion to provide high quality product and services, and I look for really good things to come in the future.”

One aspect to look forward to is building on our rich tradition in agriculture and expanding into other markets like residential housing, and home and hobby. “Our buildings are becoming more diverse,” Mark notes. “We’re already constructing pole barn homes, or shouses as they’re sometimes called, with great success.”

With new leadership beginning to take over the reins, our commitment to high quality products and service, as well as our dedication to being a stable, employee-friendly company and good corporate citizen, remain steadfast, Mark concludes.

Lester’s future is bright, indeed.