Pole Barn Planning Process: Fast, Smooth and No Surprises

December 28, 2020

Back in the day, planning for any type of pole barn could take weeks using the pencil-and-paper approach to create floor plans and elevation drawings. Today, with Lester Building’s on-demand design, engineering and pricing system, Improv®, customers can enjoy the industry’s fastest building planning experience in the comfort of their home, office or wherever a laptop can travel.

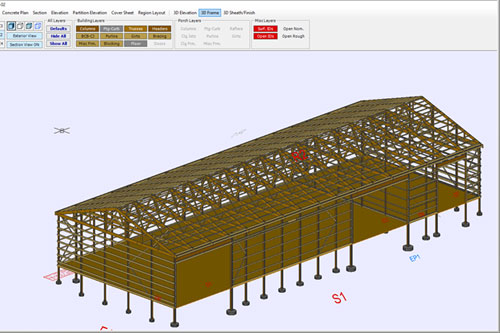

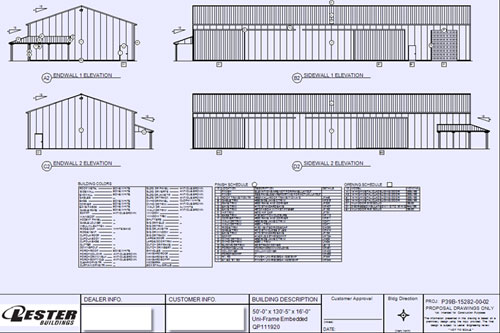

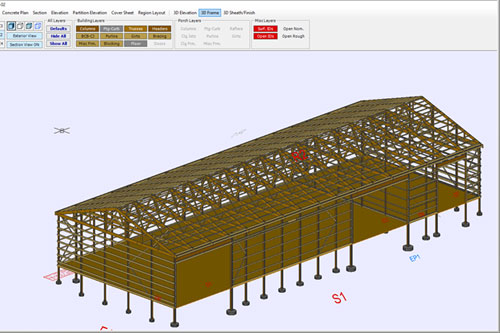

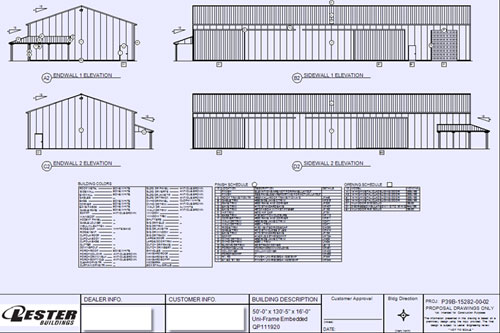

Developed exclusively by Lester, Improv is unlike any other design and pricing software. It provides accurate, on-demand building design, engineering and pricing in the time it takes to enter specifications. What’s more, Improv also produces professional floor plan, elevation and 3D drawings that oftentimes can be immediately used for permit purposes.

To give you a taste for how easy it can be to see your dream building come to life, we compiled the following experiences from customers who benefitted from working with Lester Buildings and Improv.

To be honest, Gary commented, “I was surprised at how easy the design process was. [A Lester representative] came out to our house and we sat down at our island bar. He had his computer with him and pretty much designed the building right there.”

To accommodate the door height requirements and code restrictions, Lester was able to use Improv to customize the Hiscock’s design so that the doors actually open up inside the building’s rafters. Once they had the preliminary drawings, they worked with the door company to ensure the unusual design would work. “I was impressed,” Gary admitted. “We had a lot of people look at the design – some of them other builders – and at first they were skeptical, but they wound up being impressed, too. Everything was designed excellently, and the doors work well.”

Construction began November 1 and the Hiscocks were able to safely stow their equipment right on schedule.

And as for the price estimate? “It was right on,” Gary reported. “There were no extras, no surprises.”

As John was securing a 10-acre site he also began working with Lester Buildings to generate floor plan and elevation drawings for his soon-to-be 60 x 80-foot building.

“I had a pretty good idea of what I wanted,” John said. “Because of the nature of the business, we were designing something that would increase the efficiency of our workflow. So, I met with our Lester representative and gave him the information. He came back in a short time with the initial drawings and we went through a couple of iterations based on his input and our feedback – and that was it, really.

“All in all, it was quite a smooth process, which is what I expected. And I have very high expectations,” he laughed.

The entire planning process consisted of an initial meeting to discuss what Adam wanted and a subsequent get-together to review and tweak the drawings and cost estimates.

“I actually expected the process to go well because Lester has a good reputation,” Adam said. “So, I wasn’t surprised that I only had to meet with Ron a couple of times at my kitchen table to walk through the project.”

The resulting structure, a 30 x 40-foot building with an upstairs attic for storage, is complete with a finished cement floor, heat and electricity. “My expectation was that the process was going to be smooth and that I’d have a good product at the end,” Adam said. “And that’s what I got.”

As the system prompts questions, your Lester representative inputs specifications. When you reach the end of the questions, Improv generates the floor plans and elevation drawings and details the price estimate down to each building component, even the amount of labor required.

Once that first customer meeting concludes, the initial schematics are then sent to the Lester Buildings office in Lester Prairie, where a skilled draftsman designs the final documents.

There’s no need to make the pole barn sales process a long, complicated experience! Set up a meeting with your local Lester dealer or rep to get started.

Developed exclusively by Lester, Improv is unlike any other design and pricing software. It provides accurate, on-demand building design, engineering and pricing in the time it takes to enter specifications. What’s more, Improv also produces professional floor plan, elevation and 3D drawings that oftentimes can be immediately used for permit purposes.

Improv produces professional 3D drawings.

To give you a taste for how easy it can be to see your dream building come to life, we compiled the following experiences from customers who benefitted from working with Lester Buildings and Improv.

A Place for His Toys

Gary Hiscock wanted to shelter “all of his toys,” as his wife Jan jokingly referred to their recreational equipment, from harsh winters. The retired couple live on a lake and own a fifth wheel camper, a boat and other summertime recreational gear. The challenge was that, according to local building codes, the structure couldn’t be more than 14 feet high; but Gary’s fifth wheel was 13’ 6” high, so he needed 14-foot doors on the building. Adding to the challenge: Gary needed the structure constructed and ready for use by December 1 – and it was already the beginning of September when the Hiscocks and Lester started working together.To be honest, Gary commented, “I was surprised at how easy the design process was. [A Lester representative] came out to our house and we sat down at our island bar. He had his computer with him and pretty much designed the building right there.”

To accommodate the door height requirements and code restrictions, Lester was able to use Improv to customize the Hiscock’s design so that the doors actually open up inside the building’s rafters. Once they had the preliminary drawings, they worked with the door company to ensure the unusual design would work. “I was impressed,” Gary admitted. “We had a lot of people look at the design – some of them other builders – and at first they were skeptical, but they wound up being impressed, too. Everything was designed excellently, and the doors work well.”

Construction began November 1 and the Hiscocks were able to safely stow their equipment right on schedule.

And as for the price estimate? “It was right on,” Gary reported. “There were no extras, no surprises.”

A Place for His Business

John McGreavey needed a building to serve as storage as well as a facility for truck and trailer maintenance. “I purchased Mini Biff, a portable toilet business, that was located on the farm of the family who owned it previously. Part of the purchase agreement was that I’d move the operation off the farm within 12-18 months.”As John was securing a 10-acre site he also began working with Lester Buildings to generate floor plan and elevation drawings for his soon-to-be 60 x 80-foot building.

“I had a pretty good idea of what I wanted,” John said. “Because of the nature of the business, we were designing something that would increase the efficiency of our workflow. So, I met with our Lester representative and gave him the information. He came back in a short time with the initial drawings and we went through a couple of iterations based on his input and our feedback – and that was it, really.

“All in all, it was quite a smooth process, which is what I expected. And I have very high expectations,” he laughed.

A Place for His Hobby

Adam Froemming wanted a pole barn shed to house his passion for woodworking, namely cabinet and furniture making, as well as storage. Having grown up around near Lester’s headquarters, he was familiar with Lester Buildings and knew he wanted to work with the company.The entire planning process consisted of an initial meeting to discuss what Adam wanted and a subsequent get-together to review and tweak the drawings and cost estimates.

“I actually expected the process to go well because Lester has a good reputation,” Adam said. “So, I wasn’t surprised that I only had to meet with Ron a couple of times at my kitchen table to walk through the project.”

The resulting structure, a 30 x 40-foot building with an upstairs attic for storage, is complete with a finished cement floor, heat and electricity. “My expectation was that the process was going to be smooth and that I’d have a good product at the end,” Adam said. “And that’s what I got.”

Improv also produces exact floor plan and elevation drawings.

More Bbout Improv

From doors and windows to porches and overhangs, the number of options available in pole barn design can feel overwhelming, especially if you’re going through the design process for the first time and are wondering, “What will my pole barn look like?” Fortunately, Improv takes the mystery out of the process and enables you to move quickly through myriad choices, and even make changes on the fly.As the system prompts questions, your Lester representative inputs specifications. When you reach the end of the questions, Improv generates the floor plans and elevation drawings and details the price estimate down to each building component, even the amount of labor required.

Once that first customer meeting concludes, the initial schematics are then sent to the Lester Buildings office in Lester Prairie, where a skilled draftsman designs the final documents.

There’s no need to make the pole barn sales process a long, complicated experience! Set up a meeting with your local Lester dealer or rep to get started.